Manufacturer of Packaging Machine – Smart, Strong & Easy Packing Solutions

Welcome to WeighnPack, a trusted manufacturer of packaging machine solutions for factories, warehouses, and production units. We build machines that fill fast, weigh correctly, and pack safely.

If you want packaging machines that work smoothly every day, save labor cost, and increase production speed — you are at the right place.

We design and manufacture automatic packaging machines, industrial packing systems, and custom filling solutions for many industries.

Why Choose WeighnPack as Your Packaging Machine Manufacturer?

Not all machine makers understand real factory problems. We do.

At WeighnPack, we focus on simple operation, strong build, and long life.

What You Get From Us:

-> Easy-to-use machines

-> Strong steel body

-> Accurate weighing system

-> Low maintenance cost

-> Fast packing speed

-> Custom machine design

-> After-sales support

As a professional packaging machine manufacturer, we make machines that work hard like your business.

Complete Range of Packaging Machines We Manufacture

We produce different types of packing and filling machines for different materials.

Jumbo Bag Packing Machine

Our Jumbo bag Packing Machine is perfect for packing large bulk materials like:

-> Plastic granules

-> Fertilizer

-> Cement

-> Fly ash

-> Minerals

-> Grains

These machines can handle heavy weight bags safely and fill them with high accuracy. They reduce manpower and increase production speed.

Liquid Filling Machines

We manufacture high-quality Liquid Filling Machines for:

-> Oil

-> Water

-> Chemicals

-> Paint

-> Syrups

-> Food liquids

These machines provide clean filling, no spillage, and exact volume control. They are suitable for bottles, cans, and containers.

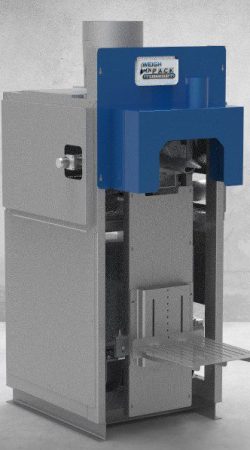

Stationary Packing Machine

Our Stationary Packing Machine is designed for fixed production lines. It is ideal for:

-> Continuous packing

-> Factory floor operations

-> Heavy material handling

This type of machine gives stable performance, strong output, and long working life.

Paper Valve Bag Filling Machine

The Paper valve bag filling machine is used for cement, powder, and fine materials. It helps in:

-> Dust-free packing

-> Fast bag filling

-> Strong bag sealing

-> Clean workplace

This machine is widely used in cement plants and chemical factories.

Our Premium Product Range

Jumbo Packing Machines

(100 kg and Above)

Our jumbo packing machines are built for heavy-duty operations, ideal for industries dealing with large-scale packaging.

Material Options: Available in MS steel, SS or other customizable materials.

Weight: Over 1000 kg, ensuring stability and durability.

Longevity: Built to last 12–15 years with minimal heating and low maintenance.

Applications: Widely used in Gujarat, Maharashtra, Rajasthan, Tamil Nadu, and other industrial hubs.

Whether you need a machine for bulk grain packaging, or cement, our jumbo packing machines deliver unmatched accuracy and reliability.

Vertical Packing Machines

Best for powders such as cement, maize starch and other materials.

Horizontal Packing Machines

Perfect for low density materials like pigments and similar products.

Stationary Packing Machines

Our stationary packing machines are versatile and cater to a variety of packaging needs. Available in three types, they are engineered for specific material characteristics:

Auger Packing Machines:

Designed for products which are difficult in flowability or for low filling speed.

Specifications: Weight: 700–1000 kg

Customization: Tailored to suit your operational requirements, ensuring precise weight accuracy and superior efficiency.

We assist in selecting the right machine for your needs and offer factory visits to provide firsthand experience with our products.

How Do We Check the Suitable Machine?

At Weigh N Pack, we take pride in delivering packaging solutions that are not only high-performing but also perfectly aligned with your specific operational requirements. To ensure that you receive the most suitable stationary packing machine for your business, we follow a meticulous process that evaluates every aspect of your materials and needs. Here’s a detailed overview of how we determine the best machine for you:

We perform extensive in-house testing to simulate real-world usage scenarios. This allows us to understand how your materials behave during the packaging process. Our state-of-the-art facility is equipped with advanced testing tools that help us evaluate the compatibility of your materials with our machines. From flow characteristics to packaging accuracy, every detail is examined to ensure seamless operation once the machine is deployed.

Material density is a critical factor in selecting the right machine. We analyze the density of your materials to ensure that the machine can handle the load effectively. Whether you’re dealing with lightweight powders or denser granular materials, our team ensures the chosen machine is capable of maintaining accuracy and efficiency without any operational strain.

The size and shape of the particles significantly impact how materials move through the packaging system. We work closely with our clients to gather precise data on particle sizes and their distribution. For example, fine powders require machines with advanced sealing and anti-leakage capabilities, while larger granules or bulkier items need specific auger or conveyor mechanisms for smooth handling.

Moisture levels can alter the flowability and weight of materials, potentially affecting the accuracy of the packaging process. Our experts measure and assess the moisture content of your materials to determine if additional machine features, such as anti-clogging or moisture-resistant mechanisms, are necessary. This ensures that the machine performs optimally regardless of material conditions.

Our team combines years of industry expertise with the insights gathered from testing to recommend the most suitable machine for your needs. Whether you require a horizontal machine for moderately hard materials like clay, a vertical machine for fine powders such as flour, or an agro-type machine for bulkier items like wool or hay, we ensure that the recommended solution is tailored to your specific requirements.

By considering these factors, we guarantee that the machine you receive will seamlessly integrate into your operations, minimizing waste, reducing downtime, and boosting productivity.

Customized Features for Enhanced Efficiency

At Weigh N Pack, we take pride in delivering packaging solutions that are not only high-performing but also perfectly aligned with your specific operational requirements. To ensure that you receive the most suitable stationary packing machine for your business, we follow a meticulous process that evaluates every aspect of your materials and needs. Here’s a detailed overview of how we determine the best machine for you:

No 1

Industry: Smart Factory Concept

Our stationary packing machines are equipped/compatible with smart factory provision, enabling seamless communication between the machine and your operational team. The Smart Factory concept transforms your packaging process by integrating automation, real-time data access, and predictive maintenance capabilities.

Predefined Data Inputs: Each machine is programmed with predefined operational data. For example, components within the machine are tracked based on their usage, and when a part nears the end of its lifecycle, the system sends automatic notifications to your team. This ensures timely replacements, reducing downtime and preventing sudden breakdowns.

Accessible Data: All operational data is easily accessible through the machine interface. This feature enables you to analyze performance trends, identify bottlenecks, and make informed decisions for improving your production process.

No 2

Advanced Maintenance Alerts

Traditional machines often operate until a critical issue leads to a shutdown, causing operational delays and costly repairs. With our advanced maintenance system, you gain:

Error Notifications: The machine categorizes issues into different levels of urgency—Low Level, High Level, and Urgent Level. This allows your team to address minor errors before they escalate into major problems.

Proactive Maintenance: The system provides early warnings for wear and tear or operational anomalies, ensuring that your maintenance team is always a step ahead. This not only reduces downtime but also extends the lifespan of your machine.

Efficient Team Coordination: With detailed error reports and notifications, your maintenance team can prioritize tasks effectively, ensuring smooth operations and minimizing production delays.

No 3

PLC-Based Machines: Superior Control and Precision

Weigh N Pack recommends PLC (Programmable Logic Controller)-based machines over traditional controller-based systems for enhanced operational flexibility and reliability.

Why PLC?:

PLC-based machines are equipped with superior processing power and customization capabilities. They can easily adapt to diverse packaging requirements, making them ideal for industries with varying material handling needs.

Benefits:

1. Improved accuracy and speed during packaging.

2. Easier integration with other automated systems in your factory.

3. Enhanced durability and resistance to system failures.

4. Greater control over machine functions for precision packaging.

Why Choose Customization?

Customizing your stationary packing machine with these advanced features not only improves your business’s operational efficiency but also helps you stay ahead in a competitive market. By adopting Industry 4.0 capabilities, predictive maintenance systems, and PLC-based technology, you can:

No 1:. Optimize machine uptime and minimize repair costs.

No 2:. Make data-driven decisions for long-term success.

No 3:. Improve coordination among your operational and maintenance teams.

No 4:. Scale your production to meet future demands seamlessly.

At Weigh N Pack, we believe that every business is unique. Our customized features ensure that your machine is tailored to meet your specific needs, delivering maximum value and performance. Let us help you build a smarter, more efficient packaging system for your business.

Strong Build Quality & Smart Technology

WeighnPack machines are built using:

-> Heavy-duty components

-> Industrial-grade motors

-> Accurate sensors

-> Advanced control panels

This ensures:

-> Less breakdown

-> More production

-> Better safety

-> Long machine life

That’s why many businesses trust us as their packaging machinery supplier and manufacturer.

Why Customers Choose Weigh N Pack Bulk Packing Machines

Industry Expertise

With years of experience in the packaging and material handling industry, we bring a wealth of knowledge to deliver solutions that exceed expectations.

Superior Quality

Our machines undergo rigorous testing to ensure durability, efficiency, and reliability. You can count on us for superior craftsmanship.

Customization Options

We understand that every business has unique requirements. That’s why we offer tailored machinery solutions to optimize your processes.

Exceptional Support

From initial consultation to after-sales support, our team is dedicated to providing a seamless experience.

Industries We Serve

Enhance your production line with our precise and efficient liquid filling machines, designed for accuracy and reliability.

Food Industries

Optimize your bag filling operations with hygienic packing machines and dependable conveyor systems that meet stringent industry standards.

Cement & building Materials Industries

Our stationary machines are best for low capacity plants for cement industries, and for building materials specially developed components with higher resistance provide a long life of wearable parts robust screw conveyors and belt conveyors are ideal for seamless material transportation in coal and cement handling facilities.

Power Plant Industries

Improve efficiency in power plant operations with our specialized equipment such as screw conveyors for fuel handling and reliable packing machines for effective packaging of power plant components.

Chemical Industries

Our durable packing machines, conveyors and material handling equipment ensure safe and efficient chemical production processes.

Pharmaceutical Industries

Meet stringent quality and compliance standards with our sanitary-grade packing machines, ideal for sensitive pharmaceutical products.

Easy Installation & Training Support

We don’t just sell machines. We support you.

Our services include:

-> Machine installation

-> Operator training

-> Maintenance guidance

-> Spare parts support

-> Technical help

We make sure your machine starts working quickly and correctly.

Why Businesses Trust WeighnPack

We are not just another packaging machine company.

We focus on:

-> Customer satisfaction

-> Honest pricing

-> Reliable performance

-> Long-term partnership

Our goal is to help your business pack faster, save money, and grow bigger.

Looking for a Reliable Packaging Machine Manufacturer?

If you are searching for a manufacturer of packaging machine that delivers quality, speed, and service, WeighnPack is ready to help.

Whether you need:

-> Jumbo bag Packing Machine

-> Liquid Filling Machines

-> Stationary Packing Machine

-> Paper valve bag filling machine

-> Or complete packaging automation

We have the right solution for you.