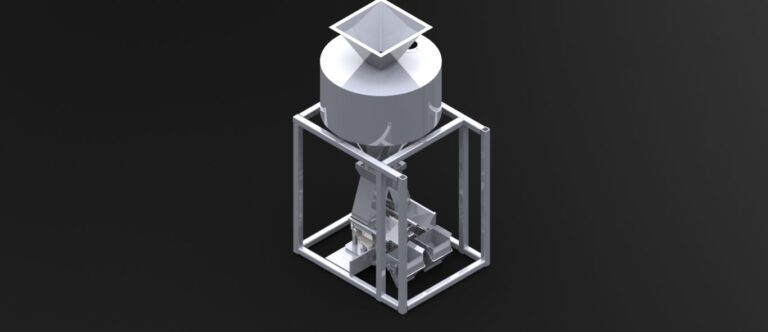

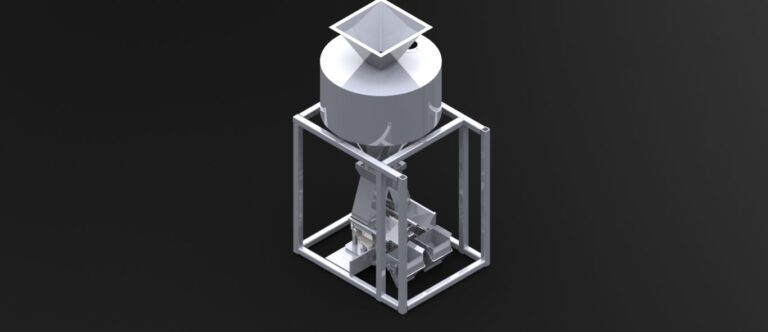

Stationary Packing Machine for Bulk Material Packing

Introduction

Packing machines have become an integral part of various industries, including food, agriculture, chemical, and pharmaceuticals. These machines help in the efficient and accurate packaging of products, ensuring their safety and longevity. In recent times, there has been an increase in demand for stationary packing machines for bulk material packing.

This essay aims to give an overview of stationary packing machines, discuss the different types of machines suitable for bulk material packing, and provide factors that industries should consider when choosing one.

A Brief Overview of Stationary Packing Machines

A stationary packing machine is a machine that packs bulk materials into bags or containers for transport or storage. These machines can pack materials like grains, coffee beans, pet food, and chemicals into different-sized bags or containers.

Stationary packing machines can be semi-automatic or fully automatic, and they have different feed mechanisms that ensure the consistent flow of materials during the packing process.

Importance of Packing Machines in Various Industries

The use of packing machines provides several benefits to various industries. For instance:

- It saves time and labor costs, as the machines can handle large volumes of materials far more quickly than manual labor

- It ensures consistent quality, thus limiting discrepancies in the weight, size, and quantity of packaged products.

- The machines improve safety by eliminating manual handling of materials, thereby reducing risks of injury to personnel.

Types of Stationary Packing Machines

The following are the types of stationary packing machines suitable for bulk material packing:

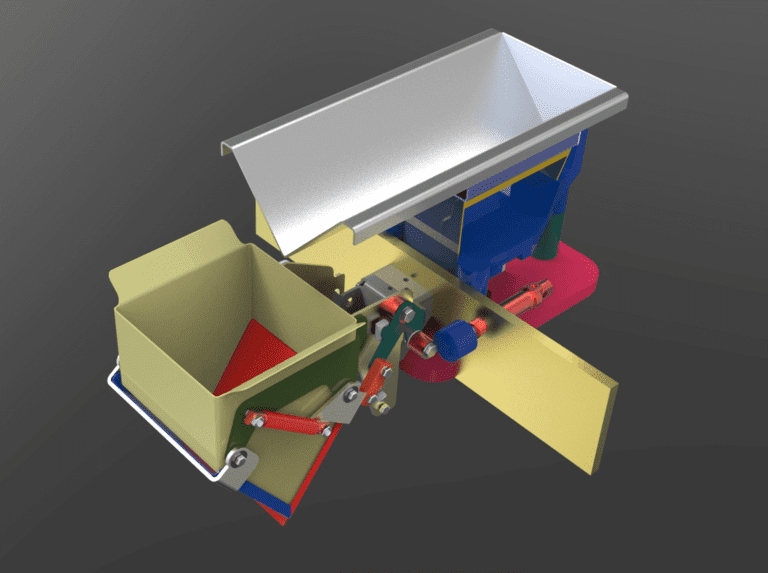

Horizontal Impeller-Type Packing Machine

This machine can weigh and pack products ranging from 10 kg to 50 kg. It is ideal for packaging materials such as flour, grains, and cement. The machine has several benefits, including:

- High packing accuracy

- Low energy consumption

- Minimal product spillage

- Easy maintenance

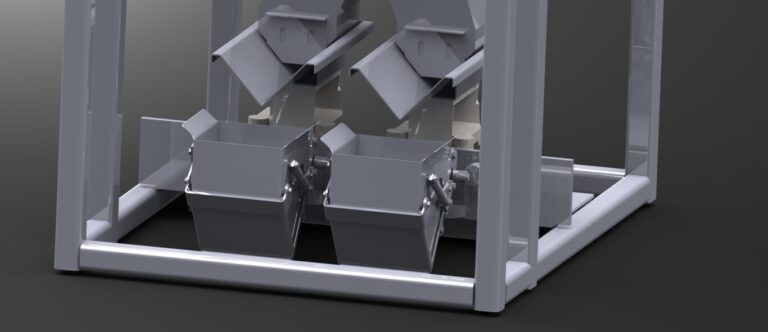

Vertical Impeller-Type Packing Machine

This machine can pack between 5 kg to 50 kg of materials. It is suitable for packing materials such as fertilizers, coffee beans, and pet food. The machine offers several benefits, including:

- Low noise level

- High weighing accuracy

- High efficiency due to its fast processing speed

- The ability to pack different sizes of bags and containers

Air-Type Packing Machine

This machine is ideal for packing bulk materials weighing between 1 kg to 20 kg. It is suitable for packing materials such as spices, milk powders, and detergents. The machine has several benefits, including:

- High production capacity

- High packing accuracy

- Ease of operation and low maintenance costs

Factors to Consider When Choosing a Stationary Packing Machine

When choosing a stationary packing machine suitable for bulk material packing, industries should consider the following factors:

Type of Product to be Packed

Industries should select a machine that is suitable for the bulk material they intend to pack. Factors such as material density, size, and flow characteristics should be considered when selecting a machine.

Production Speed and Capacity

Industries should select a machine that can handle their production speed and capacity requirements. For instance, a machine that can pack 50 bags per minute may be suitable for a company that packages 500 bags per day.

Space and Layout Requirements

Industries should evaluate their space and layout requirements to determine the size and placement of the machine. This will ensure that the machine fits well in its workspace and that there is enough room for personnel to operate it comfortably.

Budget and Cost-Effectiveness

Industries should select a machine that is cost-effective both in terms of initial investment and operational costs. A machine that requires less power, maintenance, and labor costs may be considered more cost-effective than a machine that requires high maintenance.

Conclusion

Stationary packing machines are essential for packing products in various industries. Horizontally impeller-type, vertical impeller-type and air-type packing machines are suitable for packing bulk materials. Companies should carefully consider factors such as product type, space requirements, production speed and capacity, and budget to choose the right machine for their needs. By selecting a reliable machine from top manufacturers and maintaining it properly, companies can ensure that they achieve their packing goals efficiently and effectively.

FAQs

A stationary packing machine is a machine that packs bulk materials into bags or containers for transport or storage.

Materials are fed into the machine using a feed mechanism that ensures a consistent flow of materials during the packaging process. The machine weighs the products and then packs them into bags or containers.

Stationary packing machines are used in various industries, including food, pet food, agriculture, chemical, and pharmaceuticals.

Regular cleaning, lubrication of moving parts, and timely replacement of worn-out parts can help maintain a stationary packing machine.

The different types of stationary packing machines include horizontal impeller-type packing machines, vertical impeller-type packing machines, and air-type packing machines.