Net Weighers:

Revolutionizing Weighing Processes in Industries

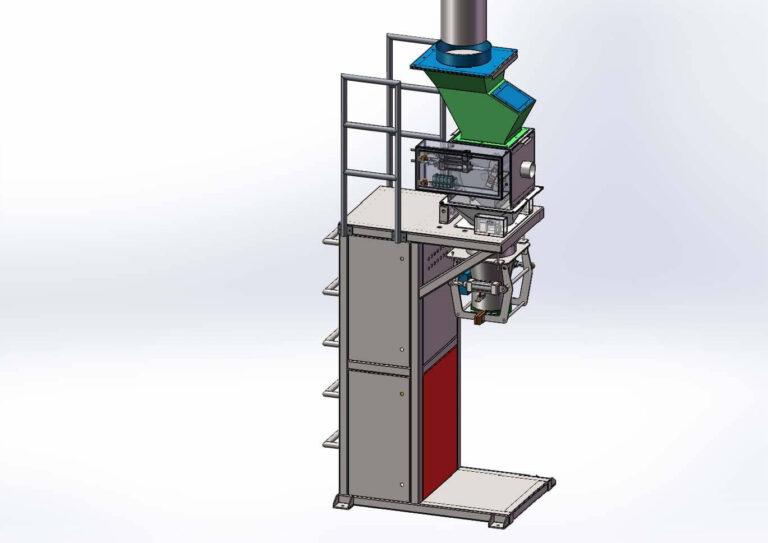

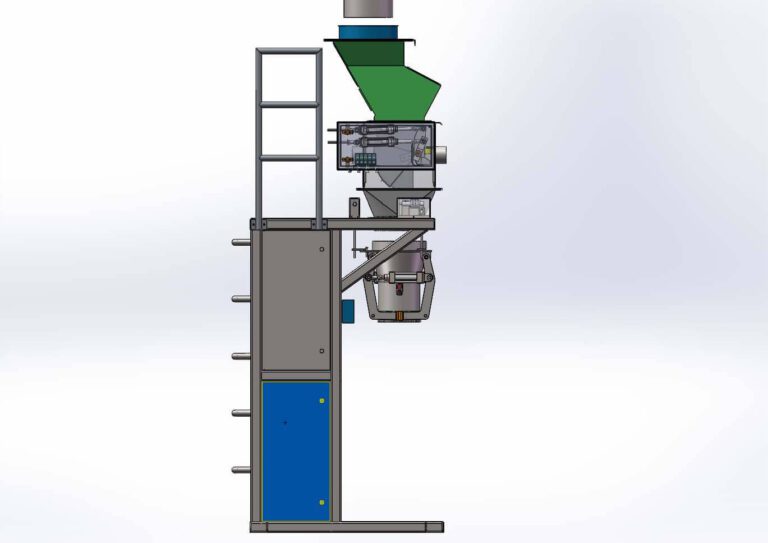

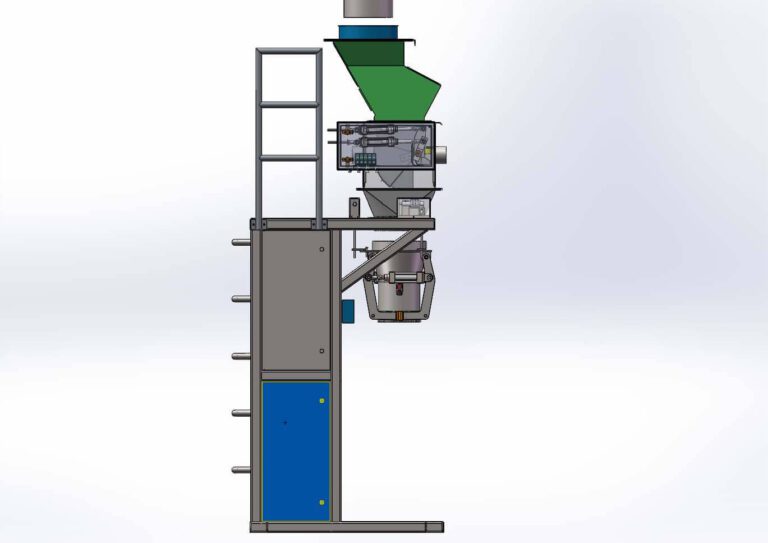

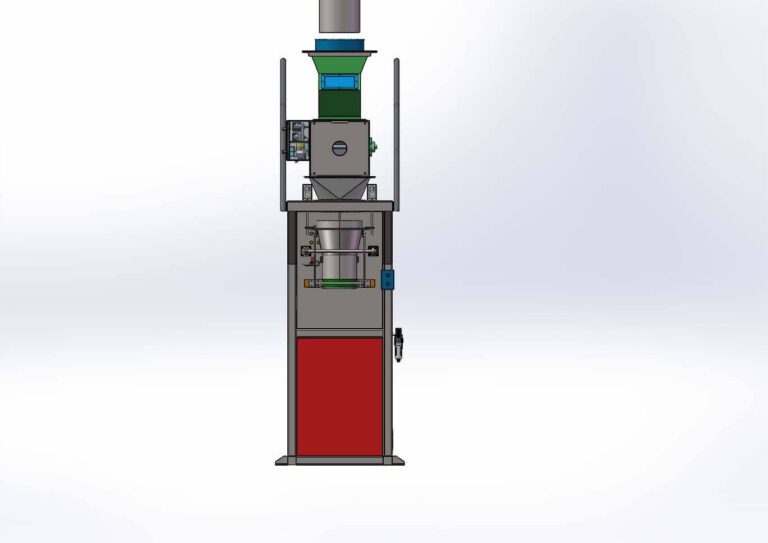

Introduction to Net Weighers

Net weighers are weighing systems used in various industries to accurately measure the weight of a product. It is an essential component in the manufacturing process, where precise measurement is vital. Net weighers are designed to provide accurate readings and increase production efficiency. Industries such as food, pharmaceuticals, agriculture, and chemicals rely on net weighers for reliable results.

How Net Weighers Work

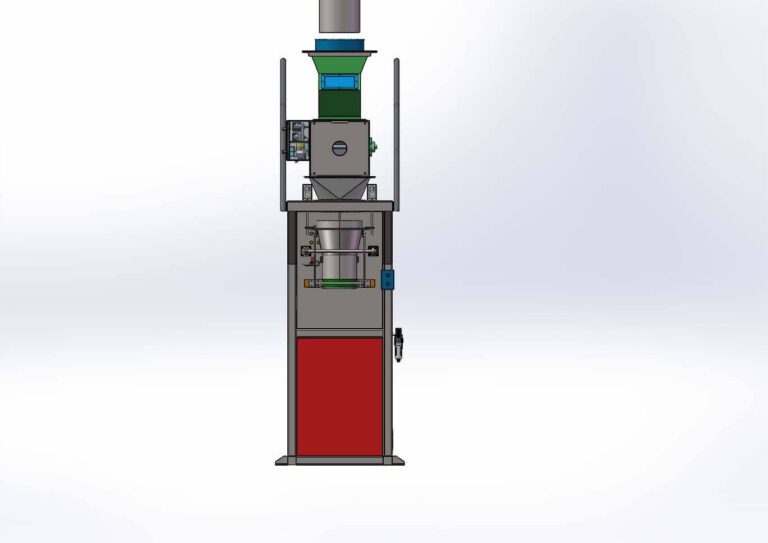

A net weigher consists of several components, including a scale platform, feeder, gate, and conveyor. The feeder mechanism controls the flow of material into the scale platform, and the gate helps to regulate the amount of product on the weigher. The scale platform accurately measures the weight of the product, and the conveyor moves the weighed material to the next stage in the process.

The weighing process of net weighers begins when the feeder transports a specific quantity of material into the weigher. Once the gate is closed, the weight of the material is measured on the scale platform. Once the net weight is achieved, the gate opens, and the conveyor delivers the weighed material to the next stage in the process. Net weighers ensure that the exact amount of material is dispensed every time and reduce waste.

Applications of Net Weighers

Net weighers are used in a wide range of industries, including:

- Food industry: Net weighers are used in the production of packaged foods, such as snack foods, cereals, and baking products, to ensure accurate measurement of ingredients.

- Pharmaceutical industry: Net weighers are used to measure and combine pharmaceutical ingredients to ensure proper dosing.

- Chemical industry: Net weighers are used in the production of chemicals, including fertilizers and pesticides, to measure the raw materials accurately.

- Agriculture: Net weighers are used in the weighing of seed, feed, and fertilizer in agricultural production.

Benefits of Using Net Weighers

The use of net weighers provides several benefits, including:

- Improved accuracy: Net weighers provide precise measurements of materials, reducing waste, and enhancing product quality.

- Increased productivity: Net weighers are designed to improve the overall efficiency of production lines, which leads to higher productivity levels.

- Cost savings: Accurate measurement helps to minimize waste, which reduces the overall cost of production.

- Enhanced product quality: Net weighers ensure consistent and accurate measurement, which leads to a standardized level of quality in the finished product.

Choosing the Right Net Weigher

When selecting the right net weigher, several factors must be considered, including:

- Weight range: The required weight range of the net weigher.

- Materials: The type of materials that will be weighed on the net weigher.

- Customization options: The available customization options for specific industry requirements.

- Maintenance and support: The level of maintenance and support required for the net weigher.

FAQs

Net weighers ensure accuracy through the use of precise measurement equipment that provides reliable readings every time.

Net weighers are commonly used in the food, pharmaceutical, chemical, and agriculture industries.

Net weighers improve productivity by streamlining the weighing process, increasing production efficiency, and ensuring reliable measurements.