Clean Filling. No Powder Loss. Safe Working.

If you handle powder, cement, chemicals, food grains, minerals, or any dusty material, you already know one big problem — dust everywhere.

Dust means:

Material loss

Dirty factory

Health risk for workers

Machine damage

Pollution complaints

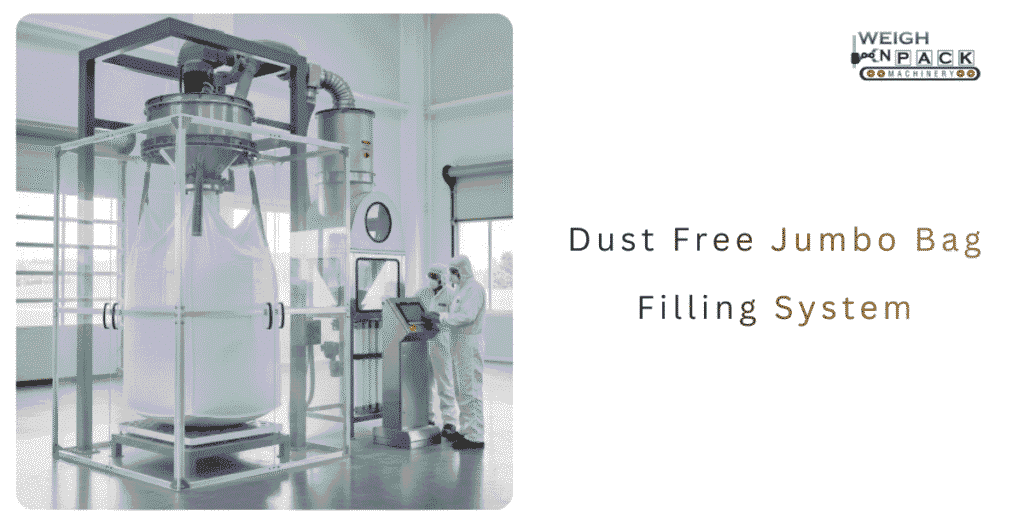

That is why industries now prefer a Dust Free Jumbo Bag Filling System.

At WeighnPack, we design advanced jumbo bag filling solutions that keep your plant clean, safe, and efficient.

If you are looking for a reliable system for bulk material packing, this page will help you understand everything in simple words.

What is a Dust Free Jumbo Bag Filling System?

A Dust Free Jumbo Bag Filling System is a special type of bulk bag packing machine that fills FIBC (Flexible Intermediate Bulk Container) bags without releasing dust into the air.

It is also called:

Dust controlled jumbo bag filling machine

Dustless bulk bag filling system

Pollution-free big bag packing machine

Dust extraction jumbo bag filler

Enclosed FIBC filling system

Dust proof bulk bag loader

This system is designed to:

✔ Fill 500 kg to 2000 kg jumbo bags

✔ Control powder leakage

✔ Capture airborne particles

✔ Maintain clean environment

✔ Improve worker safety

Why Do You Need a Dust Free System?

Let’s understand with a simple example.

Imagine you are filling 1000 kg cement in a jumbo bag.

If dust spreads:

2–5 kg material can be lost

Workers breathe harmful air

Machines get damaged

Floor becomes slippery

Pollution control issues happen

A dust free bulk bag filling system solves all these problems.

Industries That Need Dust Free Jumbo Bag Filling

Many industries need clean and controlled filling:

Cement industry

Fly ash plants

Chemical factories

Food processing plants

Fertilizer plants

Mineral and powder handling units

Pharma industry

Pigment manufacturers

If your product is powder or fine particles, you need dust control.

How Does a Dust Free Jumbo Bag Filling System Work?

Let’s understand in very simple steps:

-> Jumbo Bag Placement

The empty jumbo bag (FIBC) is placed on the machine hooks.

-> Sealed Filling Spout

The filling spout connects tightly with the bag inlet. No gap = no dust leakage.

-> Material Filling

Material flows through screw feeder, belt feeder, or gravity system.

-> Dust Extraction System

A dust collector captures extra dust during filling.

-> Weight Control

Load cells measure exact weight (500 kg / 1000 kg / 1500 kg / 2000 kg).

-> Bag Discharge

After filling, the bag is removed cleanly.

Simple. Clean. Efficient.

Main Components of a Dust Free Bulk Bag Filling System

A high-quality system from WeighnPack includes:

✔ Filling Frame Structure

Strong steel body for heavy-duty use.

✔ Load Cell Weighing System

Accurate digital weighing.

✔ Inflatable Neck Seal

Prevents dust leakage from bag mouth.

✔ Dust Collection Unit

Captures fine particles during filling.

✔ Screw / Gravity Feeder

Controls material flow speed.

✔ Control Panel (PLC Based)

Automatic operation with easy controls.

✔ Bag Lifting Hooks

Safe jumbo bag holding system.

Key Benefits of Dust Free Jumbo Bag Filling System

1. Clean Factory Environment

No flying powder in air.

Better visibility. Clean floors.

2. Worker Safety

Less breathing problems.

Better working conditions.

3. Material Saving

No powder loss.

Every kg is saved.

4. Pollution Control Compliance

Helps follow environmental rules.

5. Accurate Weighing

No overfill or underfill.

6. Faster Production

Automatic system saves time.

Types of Dust Free Jumbo Bag Filling Systems

Different industries need different systems.

-> Semi-Automatic Jumbo Bag Filling System

Operator handles bag placement.

Machine handles filling and dust control.

Best for medium production units.

-> Fully Automatic Jumbo Bag Filling System

Everything is automatic.

High speed production.

Best for large factories.

-> High Containment Filling System

Used in pharma or hazardous chemicals.

Extra dust control and sealed chamber.

Technical Specifications (Example)

Capacity: 10–40 bags per hour

Bag size: 500 kg to 2000 kg

Accuracy: ±0.2%

Material: Powder, granules, flakes

Dust control: Integrated dust collector

Power: As per requirement

Automation: PLC based

(Custom options available at WeighnPack)

Important Features to Look Before Buying

When buying a dustless jumbo bag filling machine, check:

✔ Strong body construction

✔ High accuracy load cells

✔ Efficient dust extraction

✔ Easy maintenance

✔ Spare parts availability

✔ After-sales service

✔ Customization options

WeighnPack provides all these features.

Why Choose WeighnPack for Dust Free Jumbo Bag Filling System?

WeighnPack is known for industrial bulk bag packing solutions.

We provide:

✔ Customized design as per material

✔ Heavy-duty machine structure

✔ High precision weighing

✔ Strong dust control system

✔ Energy-efficient models

✔ Fast installation support

✔ PAN India service

Our systems are suitable for cement, chemicals, minerals, food powders, and more.

Common Problems in Normal Jumbo Bag Filling

Let’s compare:

| Normal System | Dust Free System |

|---|---|

| Dust spreads everywhere | Dust controlled |

| Material loss | No loss |

| Worker complaints | Safe environment |

| Cleaning cost high | Low maintenance |

| Pollution issue | Compliant system |

Now you know why dust control matters.

Advanced Options Available

WeighnPack also offers:

Automatic bag lifting conveyor

Palletizing system

Online printing system

Data logging system

Remote monitoring

ATEX design (for explosive dust)

ROI (Return on Investment)

Many customers ask:

“Is dust free system expensive?”

Yes, initial cost is slightly higher.

But think long term:

Material saving

Less cleaning cost

Less worker health issue

Better production speed

No pollution penalties

In 1–2 years, system pays back its cost.

Safety Standards & Compliance

A good dust free bulk bag filling system should:

✔ Follow pollution norms

✔ Meet factory safety standards

✔ Reduce airborne particles

✔ Provide safe working zone

WeighnPack systems are designed keeping industrial safety in mind.

Frequently Asked Questions (FAQ)

Q1: What materials can be filled?

Powder, cement, fly ash, fertilizer, chemicals, minerals, grains.

Q2: Can it handle 1 ton jumbo bag?

Yes. 500 kg to 2000 kg capacity available.

Q3: Is dust completely removed?

Dust is highly controlled using sealed filling and dust collector.

Q4: Can system be customized?

Yes. Design depends on your material flow and factory layout.

Q5: Is installation support available?

Yes. Complete installation and training support provided.

When Should You Upgrade to Dust Free System?

Upgrade if:

Workers complain about dust

You see material loss

Pollution board warning received

Production needs increase

Factory cleaning cost is high

If you see any of these signs, it is time to upgrade.

Simple Explanation for Easy Understanding

Think like this:

If you pour flour in open air → dust spreads.

If you pour flour inside closed box → no dust.

Dust free jumbo bag filling system works like that closed box.

It controls dust and fills big bags safely.

Final Words

A Dust Free Jumbo Bag Filling System is not a luxury.

It is a smart investment for modern industries.

It keeps:

✔ Factory clean

✔ Workers safe

✔ Product safe

✔ Production fast

✔ Environment protected

If you are looking for a high-quality, heavy-duty, and reliable dustless jumbo bag filling machine, WeighnPack can help you.

We design and manufacture advanced bulk bag filling systems tailored to your needs.