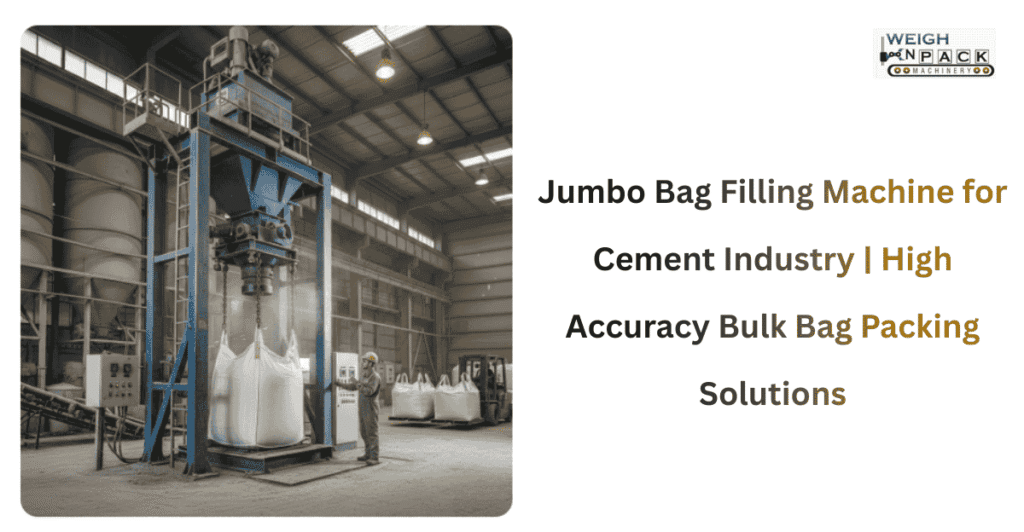

Handling cement in bulk requires precision, dust control, and consistent output speed. At WeighnPack, we manufacture and supply advanced jumbo bag packing machine for the Cement Industry designed to deliver high weighing accuracy, stable bag handling, and efficient material flow for cement manufacturers, grinding units, and bulk packing terminals.

Our jumbo bag filling systems are engineered for FIBC bags (Flexible Intermediate Bulk Containers), supporting heavy-duty cement packaging operations where reliability and productivity matter most.

If you are looking for a robust bulk bag packing solution for cement, our machines are built to meet industrial standards and continuous production demands.

What Is a Jumbo Bag Filling Machine for Cement?

A Jumbo Bag Filling Machine, also known as a Bulk Bag Filling System or Big Bag Loader, is industrial equipment used to fill cement into 1-ton, 1.5-ton, and customized capacity FIBC bags.

In cement plants, this machine is commonly installed at:

Cement grinding units

Clinker packing stations

Bulk dispatch terminals

Ready-mix concrete plants

Export packaging facilities

The system integrates weighing technology, dust extraction, bag clamping mechanisms, and vibration compaction to ensure safe and accurate cement packing.

Why Cement Plants Choose WeighnPack Jumbo Bag Filling Systems

High Weighing Accuracy

Our cement jumbo bag packers use load cell-based weighing systems that deliver consistent weight accuracy, minimizing product giveaway and reducing losses.

Dust-Free Operation

Cement handling creates airborne dust. Our machines are equipped with:

Dust extraction ports

Sealed filling spouts

Optional integrated dust collectors

This ensures clean packaging zones and worker safety compliance.

Heavy-Duty Structural Design

We use industrial-grade steel frames and reinforced platforms to handle continuous cement filling operations without vibration instability.

Faster Bag Filling Cycles

Optimized feeding mechanisms allow high throughput output, improving dispatch speed and reducing loading bottlenecks.

Compatible With All FIBC Bag Types

Our systems support:

Loop-type jumbo bags

Baffle bags

Conductive FIBC bags

Standard bulk cement bags

Technical Features of Our Cement Jumbo Bag Filling Machine

Each WeighnPack jumbo bag filling solution is engineered with industry-grade components:

Load cell weighing system

Pneumatic or hydraulic bag clamping

Adjustable filling spout height

Vibration compaction platform

Automatic weight cut-off

PLC-based control panel

Emergency safety interlocks

Optional roller conveyor integration

These features ensure stable filling performance, precise weight control, and operator safety.

Available Configurations for Cement Industry Applications

We offer multiple variants depending on your plant capacity:

Single Spout Jumbo Bag Filling Machine

Ideal for small to medium cement plants with moderate output requirements.

Double Spout Bulk Bag Filling System

Designed for high production volume cement packaging lines, allowing simultaneous filling of two jumbo bags.

Automatic Jumbo Bag Packing Line

Integrated solution including:

Bag feeding system

Conveyor transfer

Palletizing interface

Data logging and production tracking

Applications in Cement & Construction Material Sector

Our jumbo bag filling machines are widely used for packaging:

Ordinary Portland Cement (OPC)

PPC Cement

White Cement

Fly ash

Limestone powder

Gypsum powder

Construction minerals

Bulk dry materials

This makes the system suitable for cement plants, mining operations, and infrastructure material suppliers.

Why Buy Jumbo Bag Filling Machine From WeighnPack?

Choosing the right manufacturer impacts your long-term performance. With WeighnPack, you get:

In-house manufacturing support

Custom machine design options

Industrial-grade component sourcing

After-sales technical assistance

Spare parts availability

Installation guidance

Operator training

We focus on long-term operational reliability, not just machine delivery.

Compliance With Industrial Standards

Our machines are manufactured following:

Industrial safety standards

Electrical panel compliance

Load cell calibration protocols

Cement plant operational safety norms

This ensures smooth integration into existing production lines.

Customization Options Available

Every cement plant layout is different. We offer:

Custom hopper size

Height-adjustable filling spouts

Platform modifications

Conveyor integration

Remote control operation panels

Output capacity customization

You get a site-specific jumbo bag filling solution, not a generic machine.

Typical Technical Specifications (Customizable)

Bag Capacity: 500 kg to 2000 kg

Filling Accuracy: ±0.2% to ±0.5%

Power Supply: 415V / 3 Phase

Control System: PLC Based

Material Handling: Cement powder & dry bulk materials

Operation Mode: Semi-automatic / Fully automatic

Get the Best Jumbo Bag Filling Machine for Cement Industry

If you are planning to upgrade your bulk cement packaging line or install a new jumbo bag filling station, WeighnPack offers reliable, performance-driven solutions tailored to cement plant requirements.

👉 Contact our technical team today to get:

Machine pricing

Capacity recommendation

Layout guidance

Custom quotation

Installation support details