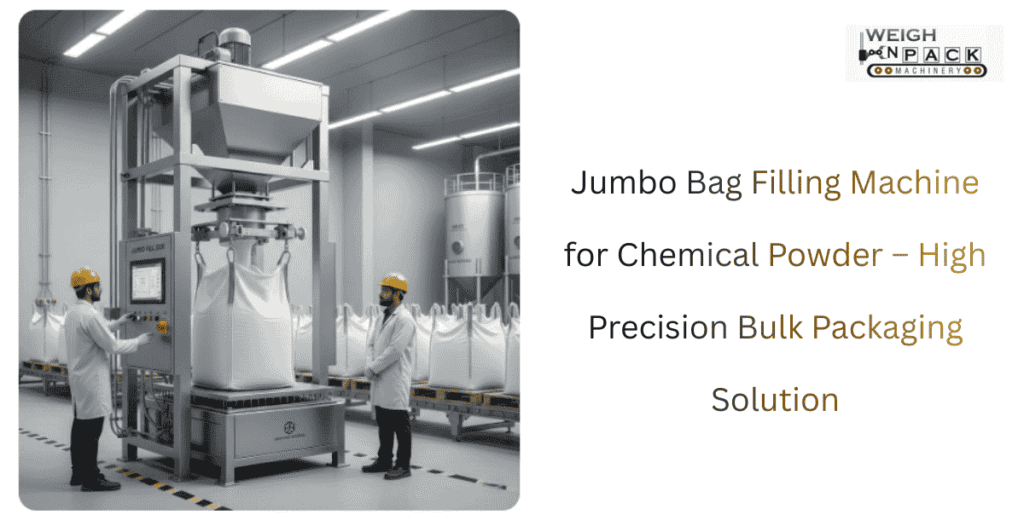

Handling chemical powder in bulk requires more than just a basic filling system. Accuracy, dust control, operator safety, and material consistency are critical. At WeighnPack, our Jumbo Bag Filling Machine for Chemical Powder is engineered to deliver reliable, high-speed, and contamination-free bulk packaging for industrial applications.

Whether you are packaging fertilizers, pigments, additives, minerals, or specialty chemical powders, our machines provide precise weighing, strong bag support, and smooth discharge control — ensuring every jumbo bag is filled efficiently and safely.

If you’re searching for a heavy-duty Jumbo Bag Packing Machine that performs consistently in demanding production environments, WeighnPack offers the right balance of automation, durability, and accuracy.

What Is a Jumbo Bag Filling Machine for Chemical Powder?

A Jumbo Bag Filling Machine, also known as a FIBC filling system, is designed to fill large flexible intermediate bulk containers (500 kg to 2000 kg capacity) with powder or granular material.

For chemical powder applications, the system is specially configured to:

Handle fine and dusty materials

Prevent material leakage

Maintain accurate weight control

Reduce product loss

Improve workplace safety

Unlike standard bulk fillers, chemical-grade jumbo bag fillers focus on controlled feeding, dust extraction compatibility, and stable bag positioning.

Why Chemical Powder Packaging Needs Specialized Equipment

Chemical powders behave differently from grains or pellets. Many are:

Highly fine and airborne

Moisture sensitive

Abrasive or corrosive

Flow inconsistent

Using a standard filling machine can cause weight variation, dust pollution, and material wastage. That’s why a dedicated Jumbo Bag Filling Machine for Chemical Powder is essential for maintaining quality and compliance standards.

Key Features of WeighnPack Jumbo Bag Filling Machine

Our jumbo bag filling solutions are built for industrial reliability and operator convenience.

High Accuracy Weighing System

Load cell-based weighing technology

Precise filling tolerance

Stable performance even at high throughput

Dust Control Compatible Design

Sealed filling spout

Optional dust extraction port integration

Cleaner production environment

Heavy-Duty Structural Frame

Strong MS or SS construction

Supports heavy bag loads without vibration

Long operational life

Adjustable Bag Handling System

Height adjustable frame

Easy bag loop hanging

Stable bag positioning during filling

Automated Operation Options

Semi-automatic or fully automatic models

PLC-based control system

Touch screen interface available

Applications of Jumbo Bag Packing Machine for Chemical Powder

WeighnPack machines are widely used across chemical and industrial sectors.

Chemical Manufacturing Plants

Detergent powder

Pigments and dyes

Additives and compounds

Fertilizer Industry

Micronutrients

Powder fertilizers

Blended chemical powders

Mineral Processing Units

Lime powder

Bentonite

Talc and silica

Pharmaceutical and Specialty Chemicals

Bulk powder packaging

Controlled environment packaging

Benefits of Using WeighnPack Jumbo Bag Filling Solution

Improved Packaging Speed

Reduce manual labor and increase daily packaging capacity.

Reduced Material Loss

Controlled discharge prevents overfilling and spillage.

Consistent Weight Accuracy

Every jumbo bag meets standard shipment weight requirements.

Safer Working Environment

Less dust exposure improves operator safety.

Lower Operational Cost

Automation reduces manpower dependency and packaging errors.

Technical Specifications (Customizable)

WeighnPack offers flexible configurations based on your production needs.

Filling Capacity: 500 kg – 2000 kg

Filling Speed: Up to 20–40 bags per hour (material dependent)

Weighing Accuracy: ±0.1% to ±0.2%

Power Supply: 415V / 3 Phase

Control System: PLC + HMI (optional)

Material Contact Parts: SS available for chemical compatibility

Why Choose WeighnPack for Jumbo Bag Filling Machines?

When buying a Jumbo Bag Filling Machine for Chemical Powder, reliability and after-sales support matter just as much as machine performance.

Industry Experience

WeighnPack designs machines based on real production challenges.

Custom Engineering

We customize feeding mechanisms, discharge systems, and automation levels as per your powder type.

Quality Manufacturing

Heavy-duty components ensure long-term operational stability.

Strong Service Support

Quick installation, training, and technical assistance.

Competitive Pricing

High performance without unnecessary cost inflation.

Things to Consider Before Buying a Jumbo Bag Packing Machine

Before finalizing your purchase, evaluate these factors:

Powder flow behavior

Required filling speed

Bag size and material

Automation requirement

Dust control needs

Space availability

Our technical team helps you select the most suitable configuration based on your plant setup.

Upgrade Your Bulk Packaging with WeighnPack

If your production depends on reliable bulk powder packaging, upgrading to a professional Jumbo Bag Filling Machine for Chemical Powder is a smart investment.

WeighnPack machines are designed to deliver:

Stable output

Accurate weights

Minimal downtime

Clean packaging operations

Whether you need a semi-automatic system or a fully automated Jumbo Bag Packing Machine, we provide tailored solutions that scale with your business.

Request a Quote Today

Looking for the best Jumbo Bag Filling Machine for Chemical Powder at competitive pricing?

Contact WeighnPack today to get:

Custom machine configuration

Technical consultation

Best price quotation

Fast delivery support

👉 Visit: https://weighnpack.com/

👉 Get expert assistance for your bulk packaging requirements.