Handling fertilizer in bulk is not simple. The product is dusty, sometimes hygroscopic, abrasive, and often moved in large volumes. This is exactly why fertilizer manufacturers, warehouses, and exporters rely on jumbo bag filling machines (also called FIBC bag filling systems or bulk bag fillers).

If you are searching for a jumbo bag filling machine for fertilizer, you are most likely trying to understand how it works, what type you need, and how to choose the right model for your plant. Let’s break it down clearly.

What Is a Jumbo Bag Filling Machine?

A jumbo bag filling machine is an industrial system designed to fill fertilizer into big bags (FIBC bags) ranging from 500 kg to 2000 kg. These machines ensure:

Accurate weight filling

Dust-controlled operation

Faster loading cycles

Safe handling of heavy materials

Unlike manual or semi-manual loading methods, automated bag fillers reduce labor dependency and product loss.

Why Fertilizer Industry Needs Specialized Jumbo Bag Fillers

Fertilizer is not like food grains or cement. It has unique challenges:

1. Dust Generation

Powdered and granular fertilizers create fine dust that can affect worker health and cause material wastage.

2. Moisture Sensitivity

Some fertilizers absorb moisture quickly, which can lead to clumping and weight inaccuracies.

3. Abrasive Nature

Materials like DAP, urea, potash, and NPK can wear down low-quality machine components.

Because of this, fertilizer bag filling machines are built with robust frames, corrosion-resistant contact parts, and sealed dust control systems.

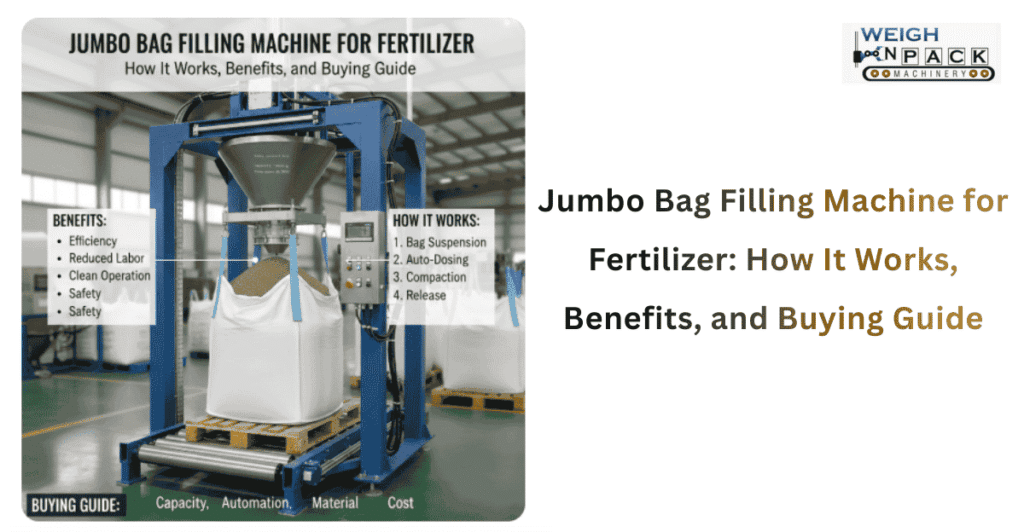

How a Jumbo Bag Filling Machine Works (Step-by-Step)

Understanding the working process helps you select the right system.

Step 1: Bag Placement

The operator attaches the jumbo bag loops to the lifting hooks and positions the bag spout at the filling nozzle.

Step 2: Material Feeding

Fertilizer flows from storage silos or hoppers through:

Gravity feed

Screw conveyors

Belt conveyors

depending on plant layout.

Step 3: Weighing and Filling

Load cells measure real-time weight. The system slows down near target weight to avoid overfilling.

Step 4: Dust Control Activation

Integrated dust extraction units capture airborne particles during filling.

Step 5: Bag Release

Once target weight is reached, the filled bag is released safely for palletizing or forklift transport.

Types of Jumbo Bag Filling Machines Used for Fertilizer

Different fertilizer plants require different automation levels.

1. Semi-Automatic Jumbo Bag Filling Machine

Best for medium-scale fertilizer plants.

Features include:

Manual bag loading

Automatic weighing

Pneumatic clamp spouts

Cost-effective setup

2. Fully Automatic Bulk Bag Filling System

Designed for high production fertilizer factories.

Advantages:

Minimal human involvement

Automatic bag clamping and release

Conveyor integration

Higher hourly output

3. Net Weigh vs Gross Weigh Systems

Net Weigh Systems

Material is pre-weighed before entering the bag

Higher accuracy

Preferred for export-grade fertilizer packaging

Gross Weigh Systems

Bag is weighed during filling

Faster operation

Suitable for bulk domestic distribution

Key Features to Look for in Fertilizer Jumbo Bag Fillers

Not all bag filling machines are built the same. Here’s what really matters.

Heavy-Duty Construction

Fertilizer handling requires:

MS or SS frames

Anti-corrosion coating

High-load bearing capacity

Dust Collection System

An efficient dust hood or extraction port helps:

Maintain clean working areas

Prevent fertilizer loss

Meet environmental safety standards

Accurate Load Cell Sensors

Weight accuracy directly impacts profit margins. Look for:

Industrial-grade load cells

Digital weighing controllers

Stable repeatability

Adjustable Filling Spout

Different bag sizes and neck diameters require flexible spout adjustment.

Safety Interlocks

Modern systems include:

Emergency stop buttons

Overload protection

Sensor-based safety logic

Benefits of Using Jumbo Bag Filling Machine for Fertilizer

Investing in the right equipment provides long-term operational advantages.

Increased Productivity

Automated filling drastically improves output per shift.

Reduced Labor Cost

One operator can manage multiple filling stations.

Better Packaging Accuracy

Consistent weight filling reduces customer complaints and compliance issues.

Cleaner Plant Environment

Dust extraction improves workplace safety.

Export-Ready Packaging

Uniform filling quality improves container stacking and transportation efficiency.

Fertilizers Commonly Filled Using Jumbo Bag Machines

These machines are widely used for:

Urea

DAP (Di-Ammonium Phosphate)

Potash

NPK blends

Ammonium Sulphate

Organic fertilizers

Micronutrient granules

Each material may require slight design adjustments depending on flow behavior.

Common Challenges and Solutions

Problem: Material Bridging

Solution: Use vibrators or agitators inside hoppers.

Problem: Dust Leakage

Solution: Install sealed spout clamps and dust suction units.

Problem: Weight Variation

Solution: Calibrate load cells regularly and use dual-speed feeding control.

How to Choose the Right Jumbo Bag Filling Machine

Before buying, answer these questions:

What is your target output per hour?

What fertilizer type are you handling?

Required bag capacity (500 kg, 1000 kg, 1500 kg)?

Available plant space?

Level of automation needed?

Clear answers help suppliers like WeighnPack recommend the correct configuration.

Maintenance Tips for Long Machine Life

Regular maintenance prevents downtime.

Clean fertilizer residue daily

Inspect load cell wiring monthly

Lubricate moving parts

Check pneumatic lines for leaks

Calibrate weighing system periodically

Preventive care directly improves machine lifespan and accuracy.

Why Industrial Buyers Prefer Trusted Manufacturers

Choosing a reliable manufacturer is just as important as machine specs.

Professional suppliers provide:

Custom-built fertilizer filling solutions

Installation support

Operator training

Spare parts availability

After-sales service

This ensures smooth long-term operation.

Final Thoughts

A jumbo bag filling machine for fertilizer is not just a packing tool. It’s a productivity system that directly affects your plant efficiency, cost control, and packaging quality.

Whether you are upgrading an existing fertilizer plant or setting up a new bulk packaging line, selecting the right filling solution makes a measurable difference in output and operational stability.

If your goal is accurate filling, dust-free operation, and scalable production, investing in a properly engineered jumbo bag filler is a smart move.