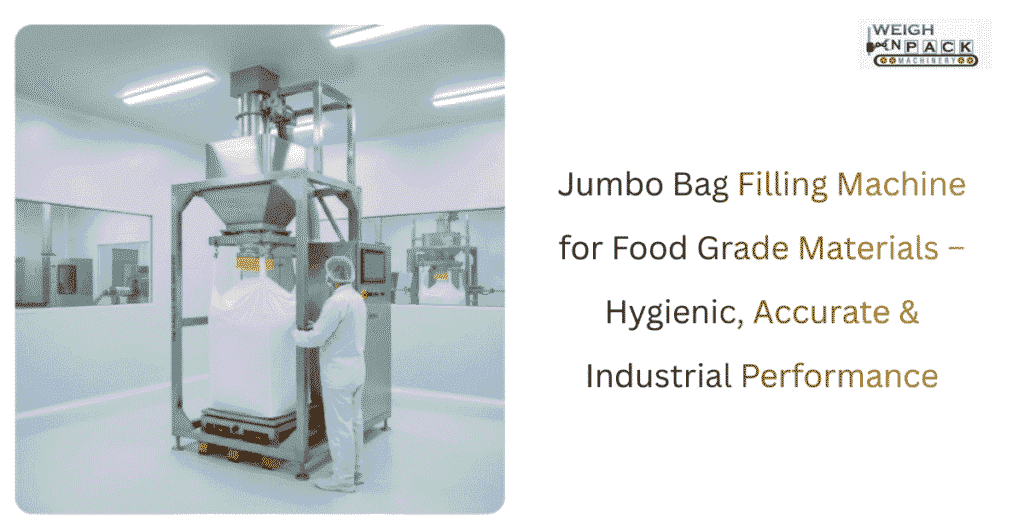

If you are handling bulk food-grade powders or granules, precision and hygiene are not optional — they are mandatory. Our Jumbo Bag Filling Machine for Food Grade Materials is engineered to meet strict food safety standards while delivering fast, accurate, and contamination-free bulk packaging.

At WeighnPack, we design and manufacture advanced jumbo bag packing machines that help food processors, ingredient manufacturers, and exporters scale operations without compromising quality.

Whether you are packing sugar, flour, rice, salt, milk powder, starch, grains, spices, or food additives, our system ensures consistent weight accuracy and clean material handling at industrial speed.

What Is a Jumbo Bag Filling Machine for Food Applications?

A jumbo bag filling machine (also known as FIBC filling system or bulk bag loader) is used to fill large flexible intermediate bulk containers with food-grade materials safely and efficiently.

Unlike general industrial bag fillers, food-grade systems require:

Hygienic contact parts

Dust-free filling

Precise weight control

Stainless steel construction

Easy cleaning access

Compliance with food safety norms

Our machines are specifically built to support these requirements while maintaining high throughput.

Why Food Industry Needs Specialized Jumbo Bag Packing Machines

Food products demand higher standards than chemicals or minerals. Using regular bulk filling systems can risk contamination, moisture exposure, or inaccurate dosing.

Our Jumbo Bag Packing Machine for Food Grade Materials solves these challenges by offering:

✔ Hygienic Stainless Steel Design

All product contact parts are manufactured using SS304 / SS316 stainless steel, ensuring corrosion resistance and easy sanitation.

✔ Accurate Weighing System

Advanced load cell technology provides high-precision weight measurement, reducing overfilling and material wastage.

✔ Dust-Free Operation

Integrated dust extraction ports and sealing mechanisms keep your packaging area clean and compliant with food plant regulations.

✔ Gentle Material Handling

Low-impact feeding systems prevent product damage, clumping, or particle breakage.

✔ High Output Efficiency

Designed for continuous production lines with stable filling speed and minimal downtime.

Suitable Food Grade Materials for Jumbo Bag Filling

Our bulk bag filling systems are suitable for a wide range of edible products, including:

Sugar and refined salt

Wheat flour and atta

Rice and grains

Corn starch and maize powder

Milk powder and dairy ingredients

Pulses and lentils

Spices and seasoning blends

Protein powder and nutritional ingredients

Baking ingredients and premixes

Whether you handle free-flowing granules or semi-fine powders, our machines adapt to your product behavior.

Technical Features of WeighnPack Jumbo Bag Filling Machine

Our machines are built for industrial performance with smart automation features:

▸ Automatic Weight Control

Ensures accurate net weight filling with programmable settings.

▸ Adjustable Filling Height

Supports various FIBC bag sizes and capacities.

▸ Bag Clamping System

Strong mechanical or pneumatic clamps hold bags securely during filling.

▸ PLC Touch Panel Interface

User-friendly control panel for easy operation and recipe management.

▸ Dust Collection Compatibility

Optional dust extraction systems available for clean packaging environment.

▸ Heavy-Duty Structure

Robust frame construction for continuous industrial usage.

Available Jumbo Bag Packing Machine Configurations

We offer flexible system designs based on your production needs:

Semi-automatic jumbo bag filling machine

Fully automatic bulk bag filling system

Single station filling unit

Double station jumbo bag packer

Gravity-fed filling system

Screw feeder-based filling system

Conveyor integrated bag loading system

Each configuration can be customized based on plant layout and production volume.

Capacity Range Supported

Our jumbo bag filling machines for food grade materials support multiple bag capacities including:

500 kg jumbo bags

1000 kg bulk bags

1200 kg FIBC containers

Custom capacity requirements

You can select throughput speed and filling rate according to your operational demand.

Why Choose WeighnPack for Jumbo Bag Filling Solutions?

When investing in industrial packaging equipment, reliability matters. At WeighnPack, we focus on engineering performance and long-term durability.

✔ Custom-Built Solutions

We design machines based on your material characteristics and packaging goals.

✔ Industry Experience

Trusted by food processors, exporters, and manufacturing plants across India.

✔ After-Sales Support

Technical guidance, installation assistance, and spare part availability.

✔ Energy Efficient Design

Optimized systems that reduce power consumption and operational cost.

✔ High Return on Investment

Reduced labor dependency, faster packaging cycles, and lower material losses.

Compliance With Food Safety Standards

Our food-grade jumbo bag packing machines are manufactured following industry hygiene practices including:

Smooth surface finish for easy cleaning

Food contact material compliance

Sealed structure to avoid contamination

Optional GMP design upgrades

This makes them suitable for modern food manufacturing environments.

Applications Across Food Processing Industries

Our jumbo bag filling systems are widely used in:

Flour mills

Sugar processing plants

Grain warehouses

Food ingredient manufacturers

Export packaging units

Agro-processing facilities

Bulk food storage centers

No matter the scale of operation, our machines deliver consistent performance.

Integration With Existing Production Lines

WeighnPack machines can easily integrate with:

Conveying systems

Silos and storage hoppers

Bag sealing equipment

Palletizing systems

Warehouse handling equipment

This ensures smooth workflow without disrupting your existing infrastructure.

Get the Right Jumbo Bag Filling Machine for Your Food Business

If you are looking for a reliable jumbo bag filling machine for food grade materials, WeighnPack provides customized engineering support to match your exact requirement.

Our experts help you choose:

Correct filling mechanism

Suitable automation level

Production capacity

Bag handling system

Dust control solution

This ensures maximum efficiency and long-term operational stability.

Request a Quote Today

Upgrade your bulk food packaging process with a high-performance Jumbo Bag Packing Machine from WeighnPack.

Contact us today to receive:

Technical consultation

Customized machine proposal

Competitive pricing

Installation guidance

Let WeighnPack power your food-grade bulk packaging with precision, hygiene, and reliability.