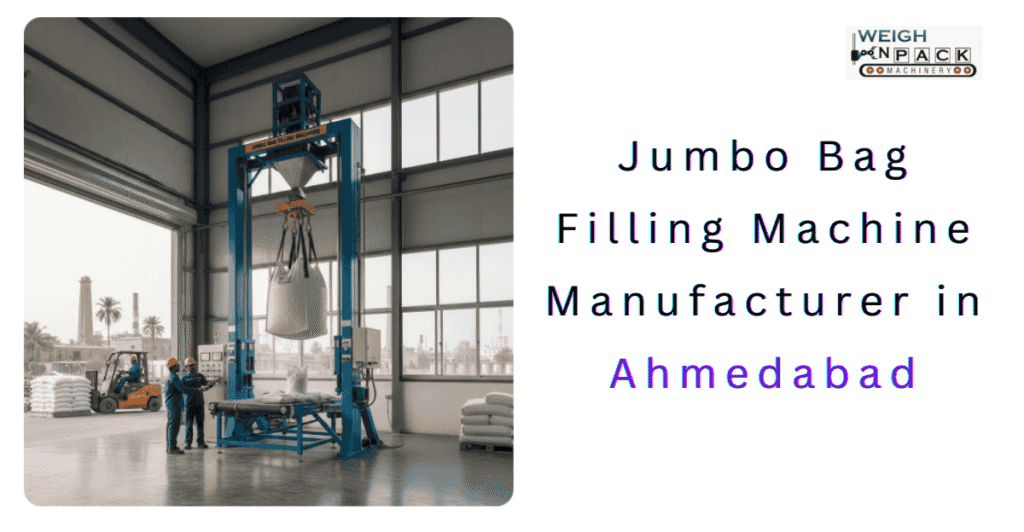

If you are looking for a reliable Jumbo bag filling machine manufacturer in Ahmedabad who understands accuracy, durability, and throughput — WeighnPack is the name industries trust. Our machines are built for factories that can’t afford downtime and need consistent filling precision for bulk materials like grains, cement, minerals, fertilizers, polymers, and chemicals.

We don’t just manufacture machines; we engineer filling solutions that reduce handling time, cut material leakage, and improve packing efficiency so your plant output doesn’t slow down.

Why Industries Choose WeighnPack

When buying a jumbo bag filling system, three things generally matter the most:

Filling accuracy – less material loss, stable weight per bag

Machine stability & build quality – long-term performance under continuous operation

Ease of operation – minimal manpower and faster bag changeovers

Our machines are designed around these practical needs. We test every unit in real-load conditions to make sure it performs the same way on your factory floor as it does in our workshop. No inflated claims, only measurable performance.

Best-Selling Jumbo Bag Filling Machines

We offer different configurations depending on bag size, filling material, and required output.

| Model Type | Ideal For | Capacity Range | Advantage |

|---|---|---|---|

| Standard Jumbo Bag Filling Machine | Powder & granular materials | 500kg – 2000kg | Sturdy frame, manual or auto weighing |

| Net-Weigh Jumbo Filler | Materials requiring tight weight accuracy | 600kg – 2500kg | ±0.5% accuracy, high productivity |

| Conveyor Based Bag Filling System | Fast line packing | 800kg – 1500kg | Faster cycle time, smooth operation |

| Bulk Material Filling Station | Mineral & cement industries | 1 ton – 2.5 ton | Heavy-duty build, dust-proof feeding |

If you are unsure which model fits your operations, we help you shortlist based on raw material, production targets, and available area in your plant.

Key Features That Improve Your Production

High-accuracy load cells to avoid under/overweight complaints

Automatic bag clamping and release for safer filling

Dust-free loading that keeps the workspace clean

Adjustable filling spout for different bag sizes

Low maintenance hydraulic system for continuous operation

Optional screw feeder, belt feeder, or gravity feeder based on material type

These features translate into better productivity, fewer manual interventions, and reduced wastage, which directly improve your bottom-line.

Where Our Jumbo Bag Filling Machines Are Used

Customers choose WeighnPack across Ahmedabad, Gujarat, and PAN India in sectors such as:

Minerals & mining

Chemical & pharma intermediates

Food grains & agro products

Cement & building materials

Plastic granules & polymers

Fertilizers & seeds

If your material flows, we can fill it.

Pricing & Delivery

The cost of a jumbo bag filling machine depends on:

Feeding method

Desired accuracy

Required automation level

Materials to be filled

Annual output

But here’s the honest part — we never compromise on build quality to reduce cost.

Instead, we customize based on your operational needs so you don’t overpay for features you don’t require.

Why Buy from a Manufacturer Instead of a Trader?

Choosing a direct jumbo bag filling machine manufacturer in Ahmedabad gives you:

Better customization flexibility

Original spare parts availability

Support technicians who understand the machine inside out

No middle-margin pricing

When machines are used daily in harsh industrial environments, the manufacturer’s engineering knowledge makes a real difference.

Let’s Talk About Your Application

If you want a machine that solves daily operational challenges instead of becoming one, WeighnPack can help.

Share your filling material type, bag weight, and expected shifts — we will suggest the right system without overselling.

Ready to Improve Your Packing Efficiency?

Call / WhatsApp: +91 99099 39002

Email: sales@weighnpack.com

Website: weighnpack.com