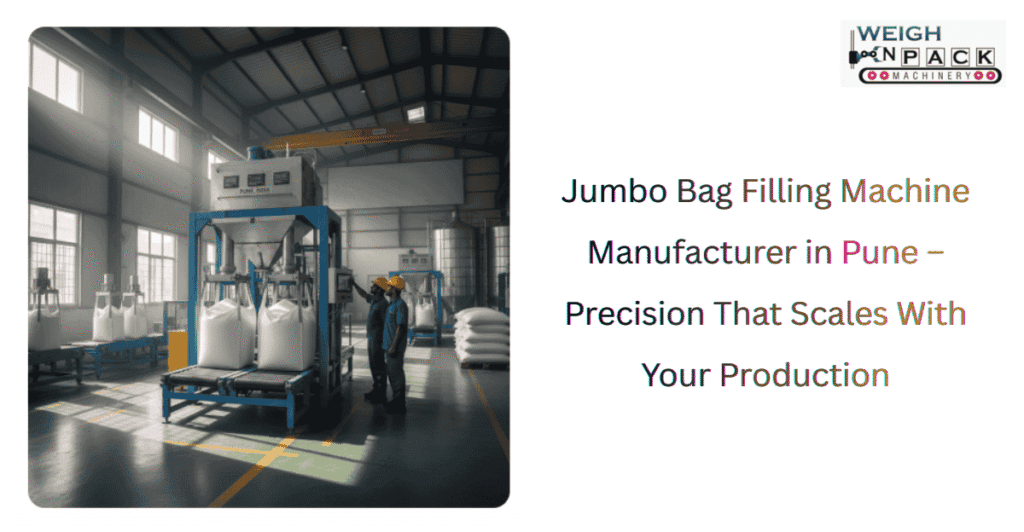

If you are searching for a Jumbo Bag Filling Machine Manufacturer in Pune, chances are you’re not just comparing prices. You’re looking for accuracy, uptime, safety, and a system that fits smoothly into your existing production line. For industries handling bulk materials—cement, chemicals, fertilizers, minerals, grains, or powders—the filling process is not a small step. It’s a critical control point.

At WeighnPack, jumbo bag filling machines are designed with one clear goal: stable, repeatable, and high-throughput bulk filling without operational guesswork.

Why Pune-Based Manufacturers Prefer Jumbo Bag Filling Machines Built for Indian Conditions

Pune is a major industrial hub with diverse manufacturing units—from MIDC zones to export-oriented plants. Here, machines face real-world challenges:

Variable raw material flow

Dust-heavy environments

Long operational hours

Skilled labor availability fluctuations

A generic imported system often fails to adapt to these conditions. That’s why working with an experienced jumbo bag filling machine manufacturer in Pune makes a practical difference—not just a logistical one.

WeighnPack designs systems that are:

Rugged, not delicate

Service-friendly, not over-engineered

Calibrated for Indian bulk materials, not lab samples

What Makes a Jumbo Bag Filling Machine Truly Production-Ready?

Many machines look similar on paper. The difference shows after installation.

1. Accurate Weighing at High Capacity

A jumbo bag filling machine must deliver consistent net weight, even when material flow characteristics change. WeighnPack integrates:

High-precision load cells

Stable frame design to reduce vibration errors

Intelligent weight cut-off logic

This ensures fewer rejections and less material loss.

2. Controlled Material Flow

Free-flowing powders, granules, or flaky materials behave differently. A reliable system uses:

Controlled feeding mechanisms

Optional vibratory or screw feeders

Anti-bridging solutions

The result: smooth filling without choking or sudden surges.

3. Operator Safety & Ergonomics

Bulk bag handling is risky if not designed properly. Our jumbo bag filling machines include:

Secure bag clamping systems

Minimal manual intervention

Dust extraction compatibility

This improves safety while maintaining speed.

Custom Jumbo Bag Filling Machines for Different Industries

As a specialized jumbo bag filling machine manufacturer in Pune, WeighnPack does not push a “one-size-fits-all” design. Systems are configured based on application.

Common industries served include:

Cement & construction materials

Chemicals & pigments

Fertilizers & agro products

Food grains & starch

Minerals & mining outputs

Each industry has different flow behavior, dust levels, and accuracy requirements. Machine configuration reflects that reality.

Integration With Existing Packaging Lines

One common concern for buyers is compatibility. A jumbo bag filling machine should fit into your workflow, not disrupt it.

WeighnPack systems can be integrated with:

Bag conveyors

Palletizing systems

Automatic bag handling units

PLC-based plant control systems

This makes the filling station part of a connected packaging line, not an isolated machine.

Why Businesses Choose WeighnPack in Pune

When buyers search for a jumbo bag filling machine manufacturer in Pune, they are usually comparing reliability more than features. Here’s where WeighnPack stands out:

Proven installations across India

In-house design and manufacturing

Application-based customization

Strong after-sales and technical support

Transparent communication from inquiry to commissioning

You’re not dealing with a trading company—you’re working with engineers who understand bulk material behavior.

Long-Term Value Over Short-Term Cost

A jumbo bag filling machine is not a short-term purchase. Downtime, recalibration issues, or inaccurate filling can cost far more than the machine itself.

WeighnPack focuses on:

Durable structural design

Stable electronics

Easy maintenance access

Long operational life

That’s why many clients come back for line expansions instead of switching supplier

Choosing the Right Jumbo Bag Filling Machine Manufacturer in Pune

Before finalizing your purchase, ask these practical questions:

Can the machine handle my material consistently?

Is the weighing system stable over time?

How fast is local service support?

Can the system scale if my production increases?

If these questions matter to you, it’s worth working with a manufacturer who builds machines for real factories, not brochures.

Talk to a Jumbo Bag Filling Expert

At WeighnPack, jumbo bag filling machines are engineered with production realities in mind—accuracy, safety, and continuity.

If you’re evaluating options from a trusted jumbo bag filling machine manufacturer in Pune, connect with our team to discuss:

Material type

Capacity requirements

Automation level

Site layout

The right solution starts with the right conversation.