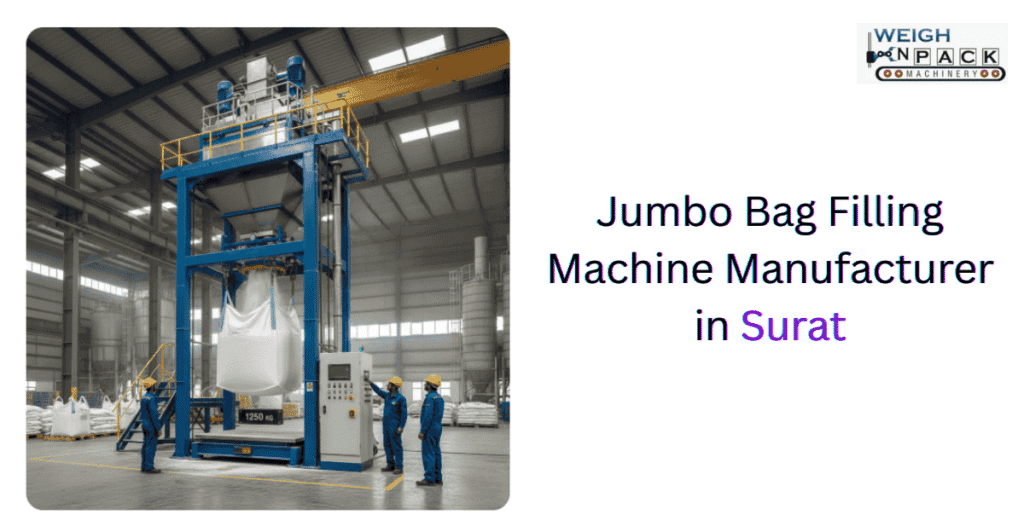

If you’re searching for a reliable jumbo bag filling machine manufacturer in Surat, you’re not just looking for a machine — you’re looking for accuracy, uptime, and long-term support. At WeighnPack, we design and manufacture heavy-duty jumbo bag (FIBC) filling machines that are built for real industrial conditions, not showroom demos.

Surat is a fast-moving industrial hub with businesses in chemicals, minerals, food processing, plastics, fertilizers, and construction materials. These industries don’t have time for breakdowns, inaccurate weights, or manual handling issues. That’s exactly where WeighnPack’s jumbo bag filling systems fit in.

Designed for Industrial-Scale Filling, Not Just Capacity Claims

A jumbo bag filling machine should do three things consistently:

Fill accurately

Operate smoothly under load

Reduce manpower and spillage

Our machines are engineered to handle 500 kg to 2000 kg jumbo bags with controlled material flow, stable bag support, and precise weighing systems. Whether you’re filling powders, granules, flakes, or free-flowing materials, the machine adapts to your process — not the other way around.

Unlike generic suppliers, we don’t sell one standard model to everyone. As a jumbo bag filling machine manufacturer serving Surat industries, we customize the design based on:

Material behavior (dusty, abrasive, hygroscopic)

Required filling speed

Bag type and loop configuration

Automation level (semi-automatic or fully automatic)

Why Surat Industries Choose WeighnPack

Surat buyers are informed. They compare machines, vendors, and service support before investing. Here’s why WeighnPack stands out:

1. Manufacturing Strength, Not Trading

We are manufacturers, not resellers. That means:

Better control over quality

Faster customization

Reliable spare parts availability

Transparent technical discussions

2. Accurate Weighing = Less Material Loss

Our jumbo bag filling machines use high-precision load cells and intelligent control systems to ensure every bag is filled within tolerance. Overfilling costs money. Underfilling causes compliance issues. We eliminate both.

3. Operator-Friendly & Safe

From pneumatic bag clamps to dust control attachments, every detail is designed to reduce operator fatigue and improve safety on the shop floor.

4. Proven Performance Across Industries

Our machines are already running in chemical plants, mineral processing units, food factories, and bulk material handling facilities across India, including Gujarat.

Jumbo Bag Filling Machine Specifications (Customizable)

While each project is different, our standard jumbo bag filling machines typically include:

Capacity: 500 kg to 2000 kg

Filling type: Gravity / Screw / Belt (based on material)

Control system: PLC-based

Bag handling: Manual or automatic loop handling

Dust control: Optional integrated dust extraction

Construction: Heavy-duty MS / SS contact parts (as required)

If your Surat facility has space constraints, high throughput requirements, or specific compliance needs, we engineer the machine accordingly.

Built for Long-Term Use, Not Short-Term Cost Cutting

Many buyers focus only on initial price. Experienced buyers look at total cost of ownership. A poorly built jumbo bag filling machine leads to:

Frequent breakdowns

Inaccurate filling

Higher maintenance costs

Production delays

As a trusted jumbo bag filling machine manufacturer in Surat, WeighnPack focuses on durability and consistency, even in demanding environments. Our machines are built to run shift after shift with minimal intervention.

Local Understanding, Nationwide Support

While WeighnPack serves clients across India, we understand the operational realities of Surat-based industries — fast production cycles, skilled but limited manpower, and the need for dependable machinery.

From pre-dispatch testing to installation guidance and post-sales support, our team ensures you’re not left figuring things out on your own after purchase.

Is Our Jumbo Bag Filling Machine Right for You?

Our machines are ideal if:

You handle bulk materials in jumbo bags

Accuracy and consistency matter to your customers

You want to reduce manual handling and spillage

You’re planning long-term production, not temporary fixes

If you’re upgrading from manual or semi-manual filling, the productivity difference is noticeable from day one.

Talk to a Jumbo Bag Filling Machine Manufacturer Who Understands Your Process

Choosing the right jumbo bag filling machine manufacturer in Surat is not about flashy features. It’s about process fit, reliability, and support.

At WeighnPack, we focus on building machines that work in real factories, under real conditions.