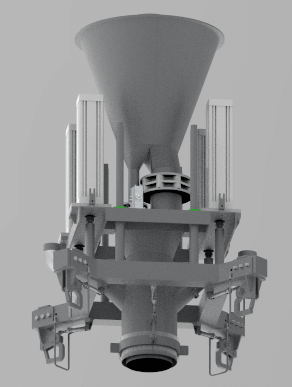

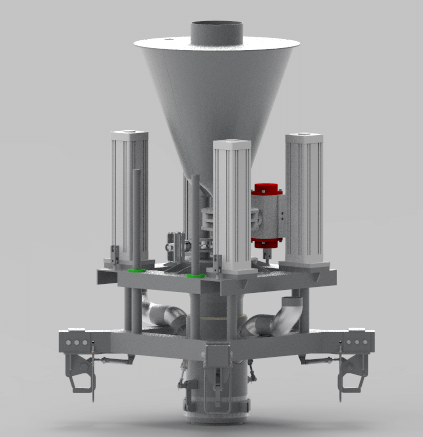

Jumbo Bag Filling Machine Manufacturer & Supplier – Industrial Bulk Bag Packing Solutions

If you are searching for a Jumbo Bag Filling Machine that works reliably in real production conditions, you need more than just a machine — you need a stable, accurate, and production-ready bulk bag filling solution.

At WeighnPack, we design and manufacture high-performance Jumbo Bag Filling Machines, Bulk Bag Fillers, FIBC Bag Filling Systems, and Big Bag Packing Machines for industries that handle heavy and high-volume materials every day.

Our machines are engineered for speed, weighing accuracy, low maintenance, and long operational life, making them ideal for continuous industrial use.

Features and Benefits of Automatic Packing Machines for Jumbo Bags

- High Weighing Capacity: Capable of handling bulk materials weighing from 100 kg to several hundred kilograms.

- Material Versatility: Constructed from MS steel or SS grade, with customization options available.

- Precision Weighing: In house developed controller and programmed which Ensures accurate weight measurements to maintain consistency.

- Robust Design: Heavy-duty construction suitable for demanding industrial applications.

- Low Maintenance: Requires minimal upkeep, reducing downtime and operational costs.

- Custom Configurations: Adaptable to unique requirements, including material type, weight capacity, and operational features.

Accuracy and precision are crucial factors for Packing Machines. Jumbo bags require precise packing to avoid errors in the final product. Automated packing machines use advanced micro processor based controller to ensure the correct amount of material is deposited into the bag. Packing rates and capacity are essential to improve the productivity of the company. Similarly, automated filling machines can customize and adapt to different bag sizes, material types, and production rates to meet the changing needs of businesses.

The machines are designed to save time. With the precise filling rate and high capacity, it takes significantly less time to fill a jumbo bag manually. The packing machines can automate the process, giving employees more time to work on other aspects of production. Additionally, safety and reliability are essential features of jumbo bag packing machines, as any error during packing can result in product damage and workplace hazards. Automated packing machines are designed to maintain safety and reliability.

Why Choose Weigh N Pack Jumbo Packing Machines?

1. Exceptional Performance

Our machines are designed to handle heavy loads of 100 kg and above, making them ideal for packaging bulk materials. With advanced weighing technology, these machines deliver precise measurements to ensure consistent results, helping you maintain quality standards in every package.

2. Built for Durability

Constructed from MS steel, with options for materials like SS grade our jumbo packing machines are built to last in even the toughest industrial environments. With a lifespan of 12–15 years, these machines resist wear and tear, prevent overheating, and require minimal maintenance, ensuring long-term operational reliability.

3. Fully Customizable

We understand that every business has unique packaging requirements. That’s why our jumbo packing machines are fully customizable. From material choices to capacity adjustments, we tailor our machines to seamlessly integrate with your production line and meet your specific needs.

WeighnPack focuses on engineering performance first, not shortcuts. Every jumbo bag filling system is designed for industrial durability and consistent output.

✔ High Weighing Accuracy

Advanced load cell technology ensures precise bag weight, reducing material wastage and rework.

✔ Heavy-Duty Construction

Rugged MS/SS frame structure designed to withstand continuous bulk handling operations.

✔ Custom Configuration Options

We offer customized hopper sizes, spout types, automation levels, and discharge mechanisms based on your product flow characteristics.

✔ Operator Safety & Easy Operation

Ergonomic design with bag clamp systems and safety interlocks improves operator comfort and reduces accidents.

✔ Low Maintenance Design

Simplified mechanical layout ensures easy servicing and minimal downtime.

Types of Jumbo Bag Filling Machines We Offer

To match different industrial requirements, WeighnPack offers multiple Types of Jumbo Bag Filling Machine designed for different materials and production capacities.

🔹 Semi Automatic Jumbo Bag Filling Machine

Best for medium-scale production units with manual bag placement and automatic weighing control.

🔹 Fully Automatic Bulk Bag Filling Machine

Designed for high-output plants requiring automated filling cycles, conveyor integration, and PLC-based operation.

🔹 Gravity Type Jumbo Bag Filler

Ideal for free-flowing materials such as grains, seeds, sugar, and plastic granules.

🔹 Screw Feeder FIBC Bag Filling Machine

Suitable for powder-based materials like cement, fly ash, chemicals, and flour.

🔹 Vibratory Feed Big Bag Filling Machine

Ensures controlled material flow for irregular and fragile products.

Technical Specifications

| Parameter | Specification |

|---|---|

| Bag Capacity | 500 – 2000 kg |

| Filling Speed | 10 – 40 Bags/Hour |

| Weighing Accuracy | ±0.2% to ±0.5% |

| Weighing System | Load Cell Based |

| Feeding Type | Screw / Belt / Gravity |

| Automation | Semi / Fully Automatic |

| Control Panel | PLC + HMI |

| Material Type | Powder / Granules |

(Customization available as per plant layout.)

Working Process of Jumbo Bag Filling Machine

The working process is simple but precise.

Step 1 – Bag Placement

The empty jumbo bag is placed on the bag holder and clamped securely.

Step 2 – Weight Setting

Desired weight is set in the control panel.

Step 3 – Material Feeding

Material flows into the bag through screw feeder, belt feeder, or gravity system.

Step 4 – Weight Monitoring

Load cells continuously monitor weight during filling.

Step 5 – Automatic Cut-Off

When target weight is reached, feeding stops automatically.

Step 6 – Bag Release

Filled bag is released for stitching and transportation.

This process ensures uniform filling and consistent output.

Applications Jumbo Bag Filling Machines Across Industries

Applications of Jumbo Bag Filling Machine. Big bag filling Our range of bulk bag fillers are used in many industries:

Food & Agriculture – Grains, flours, sugar, starches and seeds.

Chemicals & Minerals – NPK, cement, plastic beads, limestone, gypsum.

Pharma & Fine Chemicals – APIs, intermediates and fine chemicals.

Construction & Mining – Gravel, stones and all other natural materials.

Everywhere you need pneumatic bulk material packaging you’ll find our quality machinery: speed, and consistency at a low cost

Advantages of Using Jumbo Bag Filling Machine

Advantages Of Using a jumbo bag filling system offers several benefits:

-> High accuracy in weight

-> Reduced manpower requirement

-> Faster packing speed

-> Lower material wastage

-> Improved plant safety

-> Controlled dust emission

-> Better bag stability

Automation increases plant efficiency and reduces operational cost.

Jumbo Bag Filling Machine vs Manual Filling

| Feature | Jumbo Bag Filling Machine | Manual Filling |

|---|---|---|

| Accuracy | High | Low |

| Speed | Fast | Slow |

| Labor | Low | High |

| Dust Control | Controlled | High Dust |

| Productivity | High | Limited |

Automation ensures long-term savings and consistent performance.

Industries That Use WeighnPack Jumbo Bag Packing Machines

Our Jumbo Bag Packing Solutions are used across multiple sectors:

- Cement manufacturing plants

- Fertilizer and agro product units

- Food processing industries

- Chemical and pharmaceutical factories

- Plastic and polymer processing plants

- Mining and mineral handling facilities

Each industry has different product flow behavior, moisture content, and dust control requirements — which is why our machines are custom-engineered for application-specific performance.

Jumbo Bag Filling Machine Price

The price of a Jumbo Bag Filling Machine depends on:

->Capacity (500–2000 kg)

->Automation level

->Feeding system type

->Material characteristics

->Dust control system

->Customization level

For exact pricing, share your material details and production requirement.

Cement Industries

Efficiently package heavy-duty materials like Fly ash, cement, and other construction-related products with precision and ease.

Food and Agricultural Products

Perfect for large-scale packaging of grains, pulses, seeds, and other agricultural products, ensuring hygiene and accuracy.

Chemical and Fertilizer Industries

Safely package bulk chemicals, fertilizers, and similar materials while reserving their integrity during transportation and storage.

Unmatched Delivery and Installation Services

At Weigh N Pack, we provide end-to-end services to ensure a seamless experience:

Delivery

We assign dedicated delivery agents to handle logistics efficiently, ensuring safe and timely delivery of your machine. Delivery timelines are determined based on the distance from our factory to your location.

Installation

Our team of skilled technicians will manage the installation process at your site, ensuring that the machine is set up for optimal performance.

Training and Guidance

We go beyond installation by providing detailed training sessions to your staff. This ensures they fully understand the machine's operations and can maintain it effectively.

Installation & After-Sales Support

We provide:

-> Machine installation guidance

-> Electrical connection support

-> Operator training

-> Spare parts availability

-> Maintenance support

Proper installation ensures long-term performance and minimal downtime.

Regular Maintenance Services:

Keep your machine in top condition with our scheduled maintenance.

Technical Assistance:

Our support team is available to resolve any operational issues promptly.

Spare Parts Availability:

We maintain a robust inventory of spare parts for quick replacements, minimizing downtime.

Upgrades and Customizations:

Need to scale up or modify your machine? We provide upgrade services to adapt to your growing business needs.

Request a Callback

Take the first step toward revolutionizing your bulk material packaging process. Fill out our contact form today, and our experienced team will guide you through our product range and help you find the perfect solution for your requirements.

How a Jumbo Bag Filling Machine Improves Your Production Efficiency

Installing a professional Bulk Bag Filling Machine improves overall operational efficiency:

Faster Production Output

Automated filling reduces packing cycle time.

Reduced Manual Labor

Minimizes physical handling and manpower dependency.

Accurate Material Control

Eliminates overfilling and reduces material loss.

Improved Workplace Safety

Dust control and mechanical handling improve operator safety.

Better Packaging Consistency

Uniform bag filling improves transport and storage efficiency.

Get the Right Jumbo Bag Filling Machine for Your Application

Choosing the right Jumbo Bag Filling System or FIBC Packing Machine depends on:

- Material type and flow characteristics

- Required bag capacity

- Daily production target

- Automation level

- Available floor space

Our technical team helps you select the right model based on your operational needs.

->> Contact WeighnPack today to get expert guidance, competitive pricing, and customized bulk bag filling solutions.

Maintenance Tips for Long Life

To keep your jumbo bag filling machine in good condition:

-> Check load cell calibration regularly

-> Clean feeding system

-> Inspect electrical panel

-> Lubricate moving parts

-> Replace worn-out seals

Regular maintenance improves machine life and accuracy.

Safety Features

Our machines include:

-> Emergency stop switch

-> Overweight protection

-> Stable bag clamping

-> Heavy-duty frame

-> Dust control system

Safety is important for operator protection and plant compliance.

FAQs - Jumbo/Big Bag Filling Machine

A Jumbo Bag Filling Machine is an industrial bulk packaging system used to accurately fill FIBC (Flexible Intermediate Bulk Container) bags with materials like cement, fertilizer, grains, chemicals, minerals, and plastic granules. It ensures fast, dust-free and precise bag filling operations.

Both terms refer to the same equipment. Jumbo Bag Filling Machine is commonly used in manufacturing industries, while FIBC Bag Filling System is the technical term used for bulk material handling and packaging applications.

A jumbo bag filling machine can handle a wide range of bulk materials including:

Cement and fly ash

Fertilizers and chemicals

Food grains and pulses

Minerals and sand

Plastic granules and powders

The filling capacity depends on the model and configuration. Standard machines can handle 500 kg to 2000 kg per bag, with adjustable filling speed and high weighing accuracy.

Yes, jumbo bag filling machines are available in both semi-automatic and fully automatic versions. Automatic models include PLC control, conveyor integration, bag clamping systems, and dust extraction units for higher productivity.

Modern jumbo bag filling systems offer high weighing accuracy up to ±0.2% to ±0.5%, depending on load cell type and material flow characteristics.

These machines are widely used in:

Cement plants

Fertilizer manufacturing

Food processing industries

Chemical and pharmaceutical plants

Mining and mineral processing units

The price of a jumbo bag filling machine depends on capacity, automation level, customization, and optional features. For exact pricing, it is recommended to request a quotation based on your production requirements.

Yes, jumbo bag filling machines can be customized for bag size, material type, discharge method, automation level, and integration with conveyors or palletizing systems.

Regular maintenance includes:

Cleaning material contact parts

Checking load cells and sensors

Lubricating moving components

Inspecting electrical connections

Proper maintenance increases machine life and performance.